OUR HARD ANODIZING MEETS THE MIL-A-8625F STANDARD.

The constancy of our process is guaranteed by our state-of-the-art automated anodizing line.

CORROSION RESISTANCE NSS (SALT SPRAY TEST – ISO 9227)

Our process retains its characteristics: no pitting has occurred after 336 hours of exposure to salt spray.

HARDNESS IN VICKERS OF CLASS 1 (ISO-10074)

Overall value of 446 +/- 14 HV (0.05) which is classified as “Class 1” according to ISO-10074

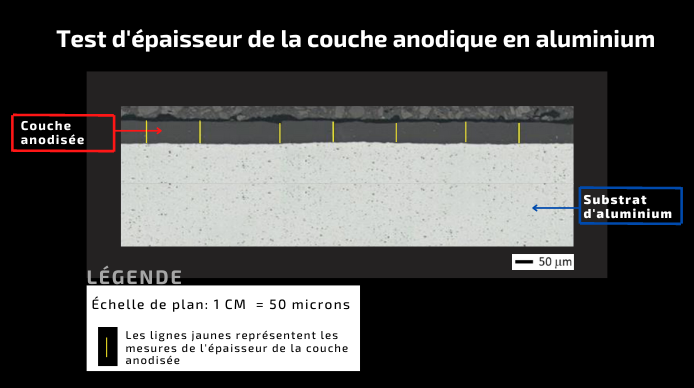

ANODIC LAYER THICKNESS: BETWEEN 25 AND 150 MICRONS

Type III hard anodizing offers the highest corrosion resistance due to its thick anodic layer.

STANDARD

The finish varies depending on the type of aluminium alloy used and the thickness of the anodic layer, ranging from titanium grey to galaxy grey.

BLACK COLORED

This type of colored anodizing is mainly suitable for the 6XXX family of alloys and is produced in accordance with MIL-A-8625F.

A flawless black finish with excellent resistance.

THANK YOU FOR TRUSTING US!

We will try to answer you within 48 hours

BUSINESS HOURS (MONDAY TO FRIDAY)

Mon. | 08 h 00 – 17 h 00 |

Tues. | 08 h 00 – 17 h 00 |

Wed. | 08 h 00 – 17 h 00 |

Thu. | 08 h 00 – 17 h 00 |

Fri. | 08 h 00 – 17 h 00 |

Sat. | Closed |

Sun. | Closed |